Moffett Automation’s hardware and software, manufactured in Ireland, combine the highest European standards with over seven decades of engineering excellence. Their solutions are used by leading integrators and satisfied customers worldwide. As part of their fully traceable and documented system, the company offers warehouse planning programs that can increase storage capacity by up to 65%. Regardless of industry, their unique optimizations, online support, and unparalleled logistics expertise enable faster throughput, efficient pallet handling, and significant cost reduction.

Trust in the quality of Irish manufacturing and the power of innovation!

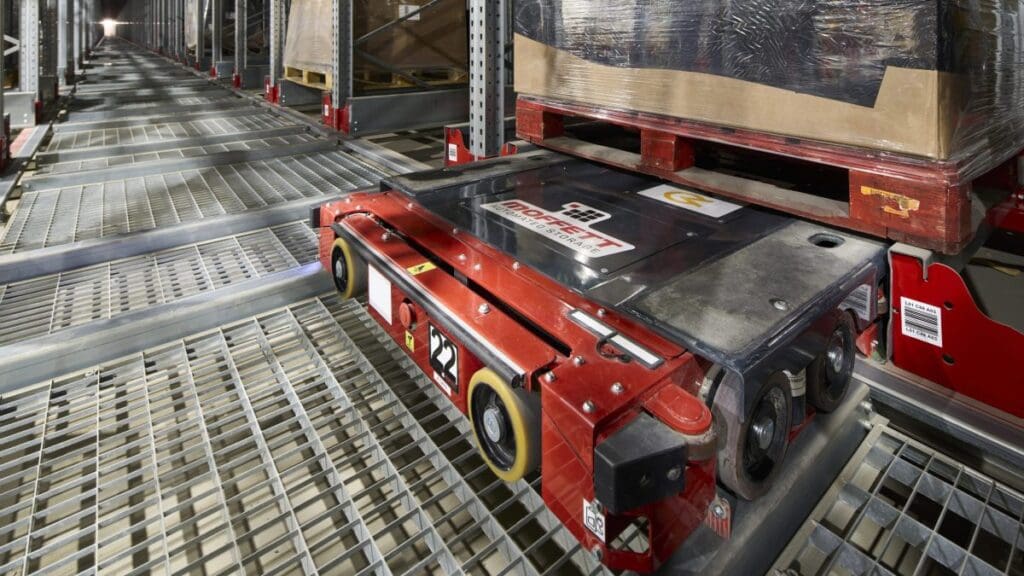

The creators of the award-winning Moffett Taxi™ system combine innovative technology with over seven decades of engineering experience to offer solutions that enable more pallets to be stored per square meter than any other automated warehousing system in the world.

Maximum storage capacity, maximum profit, and maximum opportunities—all in one system!

Thanks to its built-in redundancy, the system guarantees seamless operation while remaining fully scalable to match your company’s growth needs. It easily integrates with existing ERP systems and processing lines, providing a fully coordinated logistics solution. One of the key innovations is its 80/100 amp-hour lithium battery, which enables movement at 1.2 m/s.

The Moffett Automation system increases warehouse storage capacity by up to 65%, optimizing space utilization. This allows more pallets to be stored in the same area, significantly improving warehouse efficiency.

The Moffett Taxi™ moves at 1.2 m/s, dramatically reducing the time required for pallet movements. Its speed ensures that orders are fulfilled precisely and on time, maximizing throughput.

The system connects easily with ERP systems and processing lines, ensuring a smooth flow of data. Its scalable design allows it to grow alongside your business needs and expansion plans.

Built-in redundancy guarantees uninterrupted operation, while 24/7 online support minimizes downtime. A reliable, cost-effective solution that is always operational to tackle logistics challenges.

Moffett systems reduce the need for manual labor, lowering the risk of physical injuries and addressing warehouse workforce shortages. By automating pallet handling, employees can focus on strategic and value-adding tasks, while benefiting from a safer work environment.

The system operates with outstanding precision and flexibility, moving pallets in three dimensions: horizontally (X), vertically (Y), and in-depth (Z). Innovative Vertical Transfer Units (VTUs) allow pallets to be transported effortlessly between different warehouse levels, ensuring seamless access to any storage location.

As part of the system, every incoming pallet undergoes size and quality inspection to meet stringent standards before being placed in its designated storage location. The Moffett Taxi™ plays a crucial role in this process, capable of delivering any pallet to any specified location, maximizing storage density and optimizing space utilization.

The Moffett Automation system is fully tailored to warehouse needs, accommodating various operational demands such as order fulfillment, peak season management, or integration with existing storage technologies. Its flexible design adapts to different stages of business growth, ensuring scalability and versatility that always align with customer requirements.

With an intuitive software interface, the system can be remotely monitored and controlled. It allows for temperature sensor management, motor acceleration and deceleration adjustments, and even remote operation to swiftly address any technical issues. All of this guarantees continuous, error-free performance.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.