Seer Robotics is at the forefront of intelligent automation, offering revolutionary solutions for logistics and warehousing processes. With its autonomous mobile robot solutions and technology, businesses can achieve unparalleled efficiency and accuracy in material handling, sorting, and inventory management. Their commitment to innovation and global collaborations enables them to provide scalable, flexible, and sustainable automation solutions across various industries. Their goal is to help clients maintain a competitive edge in a rapidly evolving market.

Seer Robotics maintains close partnerships with intralogistics and industrial automation integrators, supporting them with a comprehensive portfolio of products and solutions. Their offerings include robot controllers, autonomous mobile robots, robotic forklifts, and a variety of AI-powered algorithms and software. With collaborations involving more than 1,200 integrators and robotic manufacturing partners, they have assisted over 2,000 industry partners and customers in achieving operational efficiency in both manufacturing and logistics.

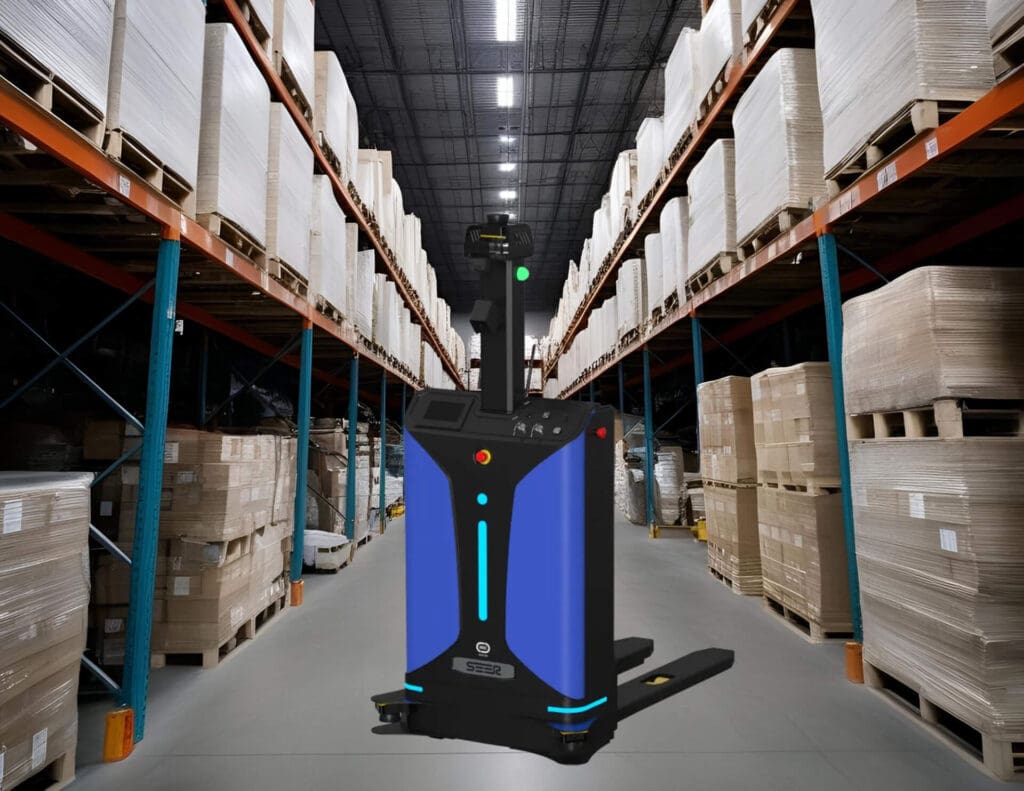

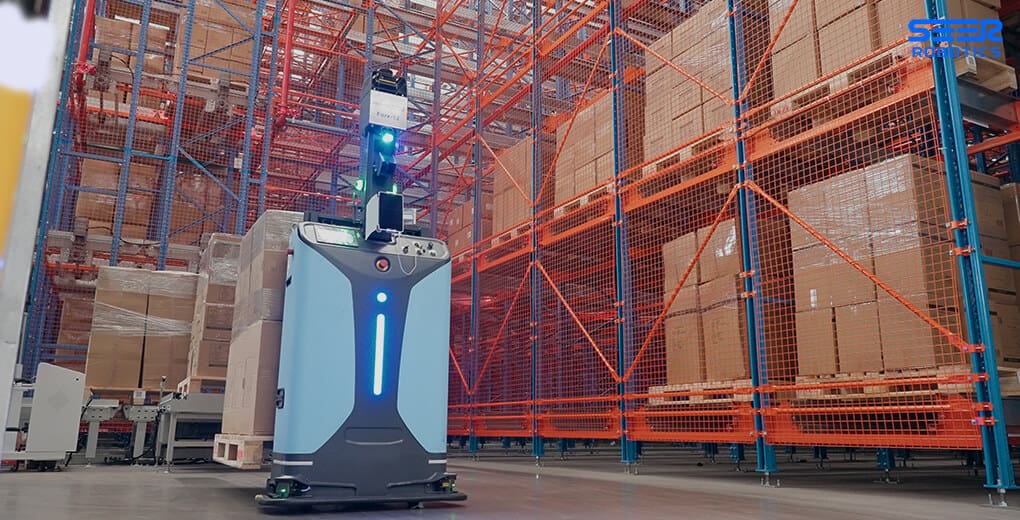

Seer Robotics offers an extensive range of mobile robots based on the integrated SRC controller. Their portfolio includes lifting robots, autonomous forklifts, carton transport robots, and much more. The product lineup is continuously expanding. Every AMR features a unified interface, and together with its software solutions, Seer Robotics provides a complete material handling and distribution system for its customers.

Based on the SRC controller and combined with Seer Robotics’ RDS (Fleet Management System) and MWMS software, various material handling tasks can be completed efficiently and seamlessly. Thanks to its modular design, it offers unparalleled reliability and stability while keeping maintenance simple.

Multiple CE certifications ensure the safe operation of Seer Robotics’ robots. Their autonomous forklifts are equipped with 3D obstacle detection and other sensors, while their AMRs feature dual laser scanners on both the front and rear, emergency stop buttons, and collision detection sensors to provide 360° safety.

The compact size and integrated climbing mechanism of the AMRs require a lower chassis height, making them suitable for a broader range of applications, even in tight spaces. Their slim autonomous forklifts enable smooth movement through the narrowest aisles.

With a diverse range of robots, Seer Robotics provides the perfect solution for every task. Their products are customizable, allowing the robotic fleet to be easily adapted to the specific needs of any warehouse.

The solution is built on Seer Robotics’ SRC series controllers, proprietary software, and versatile auxiliary components, ensuring a seamless, all-in-one fleet-building experience for customers. The goal is to enhance efficiency during the implementation and expansion phases, boost product competitiveness, and enable businesses to set up their own robotic fleet in just a few days.

This comprehensive solution includes extensive robotic offerings and advanced technology backed by Seer Robotics’ partners. It covers controller hardware, other essential components for AMR construction, the Roboshop deployment tool, and a complete software and hardware package. Additionally, it includes selection guides, installation manuals, training programs, after-sales support, as well as software updates and development services.

Building a customized robotic fleet can provide businesses with a significant competitive edge in a dynamically changing market. Tailored automated solutions align precisely with the operational needs of a given company, whether it involves material handling, order picking, or warehouse optimization.

A warehouse-specific fleet not only enhances efficiency and reduces additional costs caused by human errors but also offers flexibility, enabling rapid adaptation to market changes. Thanks to innovative technology, delivery times are shorter, inventory management is more accurate, and operational costs are lower. Additionally, scalability allows the fleet to expand according to growing demands. Such an investment secures not only present but also future competitiveness.

Request our telephone consultation in a few clicks by filling out our form. Our expert will contact you as soon as possible, but within 2 working days at the latest, using one of the contact details provided.

Using state-of-the-art robotics and artificial intelligence technologies to solve warehouse and factory logistics operations.